- +8618937185591

- +8618937185591

- ec19@zkcorp.com

- +8618937185591

As an industrial raw material, powder is widely used in cementindustry, building materials industry, metallurgy industry, chemical industry,electric power industry, paint industry, rubber industry, plastic industry,cosmetics industry, etc. The particle size of conventional industrial powder is1 ~ 10μm, and 0.1 ~ 1μm for fine powder, 1 ~ 100nm for ultrafine powder or nanopowder. The particle size by ball mill or vertical mill equipment both canreach 1 ~ 10μm, each of which has advantages and disadvantages.

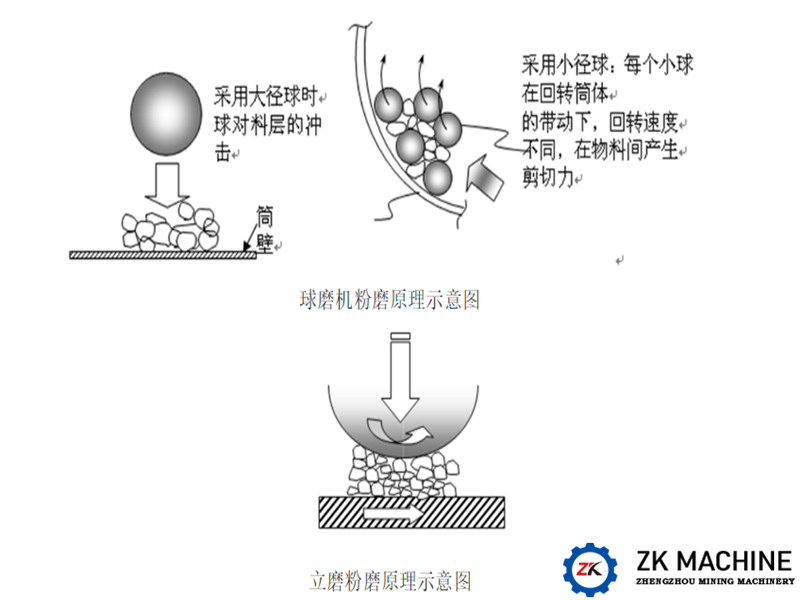

The working principle of the two is different. The grindingprinciple of the ball mill is that the large particles are crushed into smallparticles by the impact between the large steel balls, and then the smallparticles are ground by the relative movement between the small balls To achievethe purpose of grinding, the ball produced by the ball mill has a bettersphericity and a smoother surface. The working principle of the vertical millis to crush and grind large-grain materials directly into fine powder by theextrusion and shear between the grinding roller and the grinding disc. Thepowder produced by the vertical mill is in the form of flakes under themicroscope, and the sphericity is relatively difference.

Due to the different methods and principles of the ball mill andthe vertical mill, the energy consumption of the ball mill is generally higherthan that of the vertical mill, but this also has certain limitations. When theparticle size of the mill is> 13 μm (about 1000 mesh), the vertical mill isused. The energy consumption of the mill is lower. When the particle size ofthe grinding is less than 13μm, the energy consumption of the ball mill will belower. The main reason is that when the vertical mill is ground, the materialis only rolled once by the grinding roller and the grinding disc. Themedium-sized powder produced after rolling is more, the fine powder is less,and the unqualified by the separator Because the fine powder is relativelylight, it is difficult to fall onto the grinding disc for secondary grinding,so the output of ultrafine powder with vertical grinding is lower and theenergy consumption is higher; while the principle of the ball mill is just theopposite. The number of crushing and grinding is multiple and uncertain, andthere is a certain amount of over-grinding. Therefore, the proportion of finepowder produced by the ball mill is also high, and the output is relativelyhigh when grinding fine powder, and the energy consumption is low.

The above is therelevant introduction about the comparison between ball mill and vertical mill.If you want to know more equipment information, please contact ZK Corp. ZK Corpis a professional manufacturer of mining machinery and equipment. The productsare sold at home and abroad. Warmly welcome you to visit our factory!