- +8618937185591

- +8618937185591

- ec19@zkcorp.com

- +8618937185591

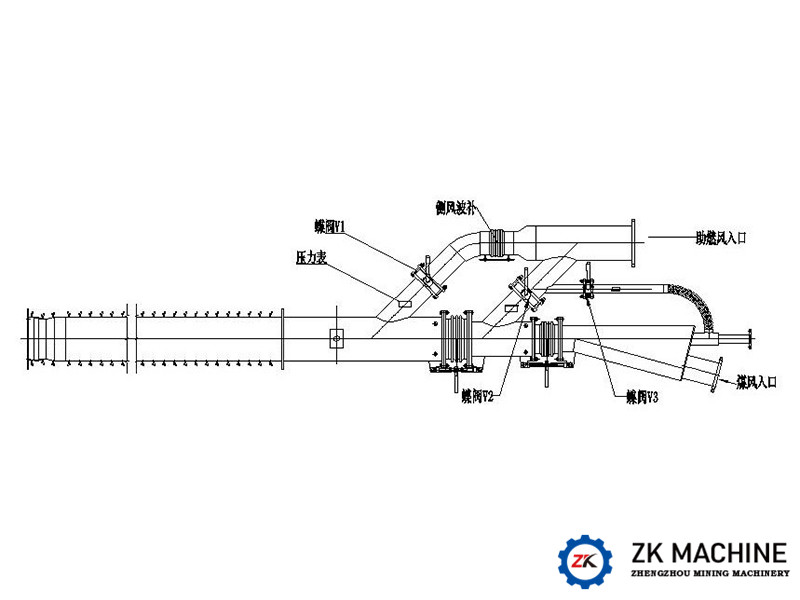

Structure of Four-channel Pulverized Coal Burner

The burner is mainly composed of pipeline, nozzle,metal corrugated compensator, butterfly valve, pressure measuring instrumentand protective layer.

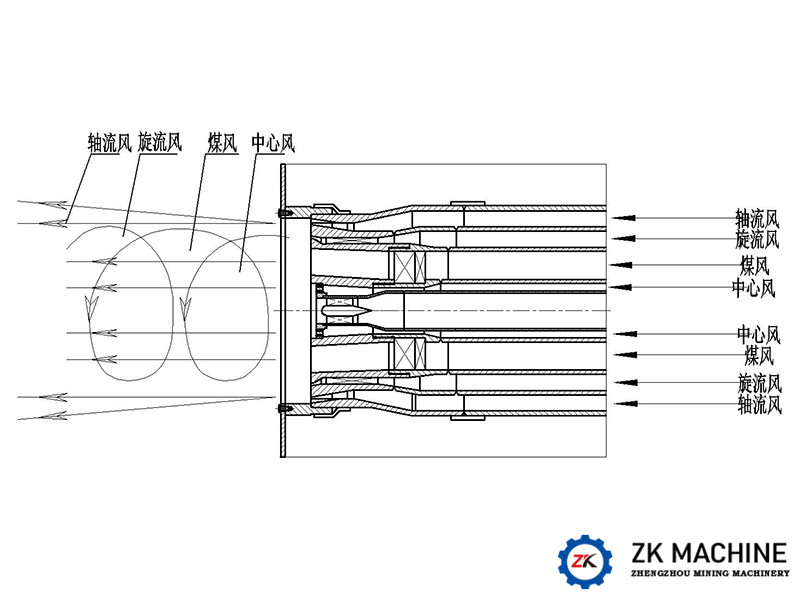

1. Pipeline: from the outside to the inside are theaxial air channel, the cyclone air channel, the fuel channel, and the centralair channel.

2. Nozzle: processed by special materials, thecross-sectional area of the outlet of the axial flow and cyclone flow can beadjusted, so as to adjust the spray speed of each wind. The entire set ofnozzles is a key component to ensure the shape of the flame.

3. Metal corrugated compensator: It is the maincomponent that connects the inner and outer pipelines of the shaft (swirl) flowwind, seals and adjusts the shape of the flame.

4. Butterfly valve: used to adjust the air volume.

5. Pressure gauge: Directly display the windpressure in the burner pipe.

6. Protective layer: namely fire-resistant castlayer.

Head Structure and Working Principle

The fuel is sprayed out from the fuel channel at acertain diffusion angle, and it is transmitted to a relatively high momentumand momentum moment by the combustion air outside. The swirling wind mixes withthe injected fuel and spirals forward at a high speed, and the axial wind thatis ejected at a high speed. The beam meets. The insertion of the axial windbeam further enhances the mixing of fuel and wind (including the surroundingsecondary air), and can adjust the degree of flame divergence. The length andthickness of the flame can be adjusted as required to achieve the desired flameshape. The role of the central wind is to promote the combustion of a smallamount of fuel and CO in the central part, so that the combustion is moresufficient, and plays a role in steady flow. Because of this combustionmechanism and the high speed of the cyclone and axial winds, the combustion isvery rapid and complete.

Offset Comparison Table

Rotary kiln diameter (m) | Offset between track center and rotary kiln center(mm) |

diameter <3m | X=50~100mm |

diameter 3~3.5m | X=100~150mm |

diameter 3.5~4m | X=150~200mm |

diameter 4~4.5m | X=200~300mm |

Diameter > 4~5m | X=300~350mm |

Note: X represents the coordinate position of the burner at the kiln mouth, and the offset direction is the material accumulation side in the kiln. The offset value is for reference only, the specific data is subject to the data of the design institute. | |

Operating Instructions of Burner

1. Preparation Before Starting

1.1 Before starting, you must read and understandthe installation files of all devices, including the following:

1.1.1 Understand the operating conditions (type,flow rate, pressure, liquid temperature, etc.) of all relevant equipment andthe site conditions.

1.1.2 Confirm that all parts of the equipment areinstalled in good condition.

1.1.3 Check the connection parts (sealing type,coupling fit, welding type conditions, etc.).

1.1.4 Turn the motor and pump by hand to checkwhether it rotates flexibly. Check whether the rotation direction of the motoris correct after power on, otherwise, reconnect the wiring.

1.1.5 Check whether the pressure gauge is installedwell.

1.1.6 Check and test whether the externalconnection of the instrument and control device is safe.

1.2 Check the following items before starting thefuel ignition device:

1.2.1 Whether the pipeline connection is correct.

1.2.2 Whether all valves rotate flexibly.

1.2.3 Whether all pipelines are cleaned to ensurethat there is no debris blocking the pipeline, otherwise it will cause ignitionfailure.

1.3 The following work should be done before theburner starts:

1.3.1 Whether all pipeline connections arecompleted.

1.3.2 Whether all pressure gauges are installed.

1.3.3 Check whether the position of the burner headis in the "0" position.

1.3.4 Check the position of the burner in the kiln.

2. Safety matters

2.1 The reason for explosion or deflagration isthat in a certain space, flammable materials and air continue to accumulate.After reaching a certain concentration, high temperature combustion occurs, andthe exhaust gas generated by the rapid combustion cannot be discharged in time.Therefore, for safety reasons, the operation of the system should be controlledunder conditions that do not produce such mixed combustion before installationand ignition.

2.2 Installation is dangerous under the followingconditions:

2.2.1 Insufficient fuel combustion;

2.2.2 Sudden flameout, unburned fuel continuouslyenters the kiln;

2.2.3 The ignition was unsuccessful due toincomplete cleaning and blocked pipelines;

2.3 The following safe chain relationships should be strictly observed:

2.3.1 When abnormal operation occurs, all valvesshould be closed, and it is not allowed to open until the fault is noteliminated.

2.3.2 Sudden power failure, all valves should beclosed immediately, and the fuel source should be closed at the same time.

2.4 Safety of combustion equipment

In the case of high temperature, in order toprevent the deformation and bending of the burner head and the hot section, thecombustion air blower must be kept open for the next use so that there is airflow in the axial flow duct to keep the burner cool. In comparison, therequired air volume is 1.5% of the primary air (minimum configuration of coolingair fan).

If the air volume in the axial air duct isinsufficient, the strength of the end of the burner will be damaged and theouter casing will be damaged.

Remember: the use pressure of the meters on thepipeline and the burner should not exceed the rated pressure requirements ofthe fan under any conditions of use, so as not to damage the fan.