- +8618937185591

- +8618937185591

- ec19@zkcorp.com

- +8618937185591

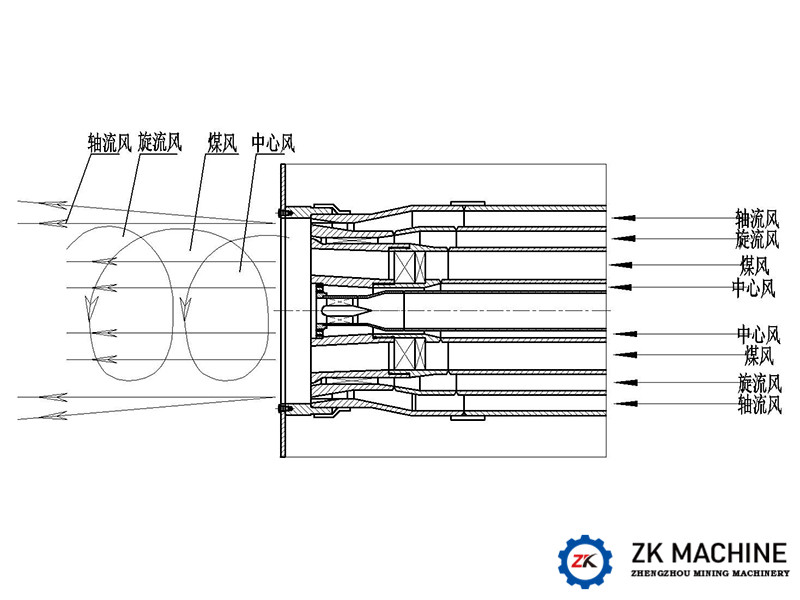

Multi-duct pulverized coal burners areburners with more than three ducts.

The arrangement form of the three-air channelburner is basically one style, that is the outer axial air, coal dust air andswirling air (from the outside to the inside), with an ignition (oil gun)channel in the middle.

In general, the center channel is not used.It is blocked.

All the four air duct burners take theoutermost air duct as the outer axial duct and the central duct as the ignitionduct. The arrangement of the other three air ducts is shown in the table:

Arrangement of air ducts (from the outsideto the inside) for four-duct burners

No. | The First | The Second | The Third |

1 | Outer axial air | Outer axial air | Outer axial air |

2 | Spiral air | Coal dust air | Coal dust air |

3 | Coal dust air | Inner axial air | Spiral air |

4 | Inner axial air | Spiral air | Inner axial air |

Central | Ignition channel | Ignition channel |

The first arrangement style: the swirl windand the outer axial flow wind are mixed at the exit, so that the axial flowwind tends to the center of the flow field, has a strong penetration to theswirl wind, so that the primary wind maintains a high swirl strength, and isconducive to the roll-suction and backflow of the combustion flue gas.

As the coal dust air is surrounded by theswirling wind and axial flow wind, the CO2 concentration at the flame root canbe appropriately increased and O2 content can be reduced.

At the same time, under the condition ofnot affecting the ignition rate, maintain a low temperature level, effectivelyinhibit the formation of thermal NOx.

The central wind is to offset the residualnegative pressure that may be generated at the root of the flame due to highswirl intensity, so as to prevent the unignited pulverized coal from beingsucked up and pressurized to the nozzle outlet to cause tempering, affectingthe steady combustion of the flame.

The second arrangement style: coal dustinside the outer axis wind flow and wind shaft between the wind flow, low speedjet coal out of the burner is different two dc wind encounter high or lowspeed, large differential wind velocity of pulverized coal and air contact withmixed, different wind speed of two axle relative motion produced by the windflow will soon be pulverized coal axial dispersion, again by rotating wind flowdisperses coal radial, fast contact air pulverized coal, to speed up the pulverizedcoal combustion.

The inner axial flow also changes thedirection of the regular directional swirl wind, which makes the swirl windbecome disordered and makes the pulverized coal disperse better.

At the same time, in the central part ofthe spiral wind flow in dc than the large air volume, high wind speed of thewind, and the first and the third kind of arrangement, the flame centertemperature is lower and is beneficial to inhibit the formation of NOx, won'tproduce the unburned pulverized coal entrainment and pressure to the nozzleexit, tempering influenced the stability of the flame burning phenomenon, forlow volatile coal and anthracite coal combustion is very favorable.

The third arrangement style: coal windbetween external direct wind and swirling wind.

The pulverized coal is immediately diffusedalong a certain Angle by the swirling air after exiting the burner.

The effect of cyclone intensity on theflame is very important in this type of burner.

When the intensity of swirling flow in thecenter of jet increases to a certain value, a circumfluence zone with annularvortex shape is established in the center of jet.

The parameters such as flame stability andcombustion intensity depend on the size and strength of vortex.

Changing the cyclone intensity is achievedby adjusting the ratio of internal and external wind.

When the swirl intensity increases, theattenuation of each velocity component along the axis direction increases, therange becomes shorter, the diffusion Angle increases, the corresponding flameshape is short and thick, otherwise the flame shape is long and thin.

The inner axial flow plays a certain rolein regulating the negative pressure of the center, and the regulating range ofthe negative pressure of the center is 0-2kPa.