- +8618937185591

- +8618937185591

- ec19@zkcorp.com

- +8618937185591

Magnesiumhas high chemical activity and exists in the form of compounds in nature indolomite, magnesite, serpentine, underground brine, salt lakes and seawater.Magnesium is a silver-white metal. Pure magnesium has the characteristics oflow density, large expansion coefficient, and low elastic modulus. Magnesiummetal has a history of more than 200 years from the development to the present,and the era of industrial production has more than 100 years.

Reduced Elemental Magnesium

Thedevelopment of magnesium can be roughly divided into three stages. The firststage: chemical method, which mainly using potassium or sodium steam to reduce moltenmagnesium chloride to obtain metal magnesium, but industrial production has notbeen achieved; the second stage: molten salt electrolysis,since 1970s, thedehydration-electrolysis method of hydrous magnesium chloride in HCl gas is amore advanced process method; the third stage: thermal reduction method,siliconthermal method to reduce magnesium oxide in vacuum, which is alsocommonly used in China at present.

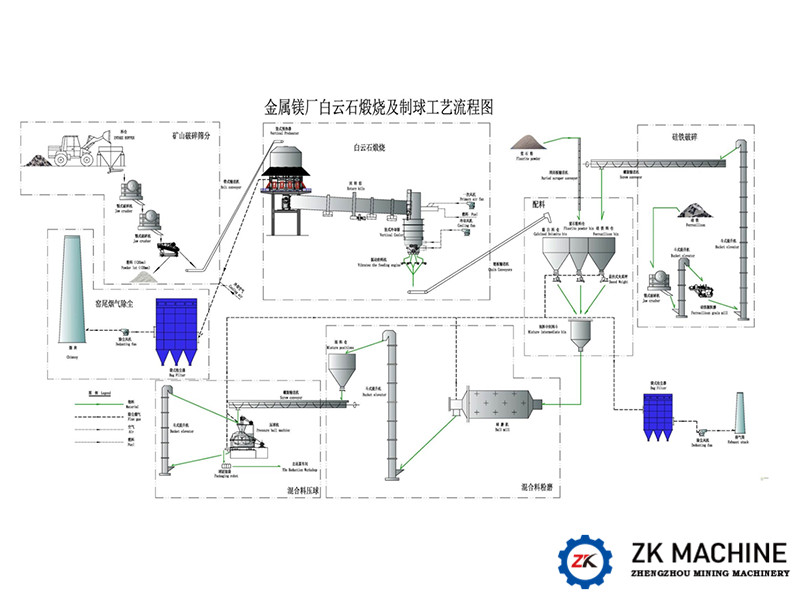

Introductionof silicothermal magnesium smelting process:

Put thepellets into a reduction furnace and heat them in vacuum environment, so thatthe silicon will reduce the elemental magnesium from the magnesium oxide in theform of magnesium vapor. The metal magnesium reduction furnace generally usesan externally heated horizontal reduction tank. At present, there are manytypes of metal magnesium reduction furnaces used in China. According todifferent fuels, they can be roughly divided into two types: reduction furnacesheated by coal gas or heavy oil and reduction furnaces using coal as fuel.

Reduction workshop-reduction furnace

China ZKCorp has successfully completed many magnesium metal projects in China. Themain feature is a new energy-saving dolomite calcination system: a verticalpreheater is installed at the end of the kiln, so that the residual heat offlue gas at the end of the kiln is directly transmitted to the dolomite , Theflue gas temperature can be reduced to 250 ~ 220 ℃, effectively recovering the heat taken away by the exhaust gasemissions, and also reduce the load for subsequent dust removal.

Thelength-to-diameter ratio of the rotary kiln is reduced from the traditional20-25 to 14-15. The shortening of the length not only reduces the heat lostfrom the surface of the rotary kiln to the surroundings, but also reduces thearea of the equipment.

The kilnhead discharge uses vertical cooler instead of a single cylinder cooler toavoid the heat loss of calcined white. The hot calcined white falling from thehead of the kiln is cooled by heat exchange with the blown secondary air, andthe air absorbs heat to increase the temperature and enters the rotary kiln tosupport combustion.

The above is the introduction of thesilicon-thermal magnesium smelting process. If you want to know more equipmentinformation, please consult us. Henan Zhengzhou Mining Machinery Co., Ltd is aprofessional mining equipment manufacturer with rich technical accumulation andproject experience. We sincerely invite you to visit our factory!