- +8618937185591

- +8618937185591

- ec19@zkcorp.com

- +8618937185591

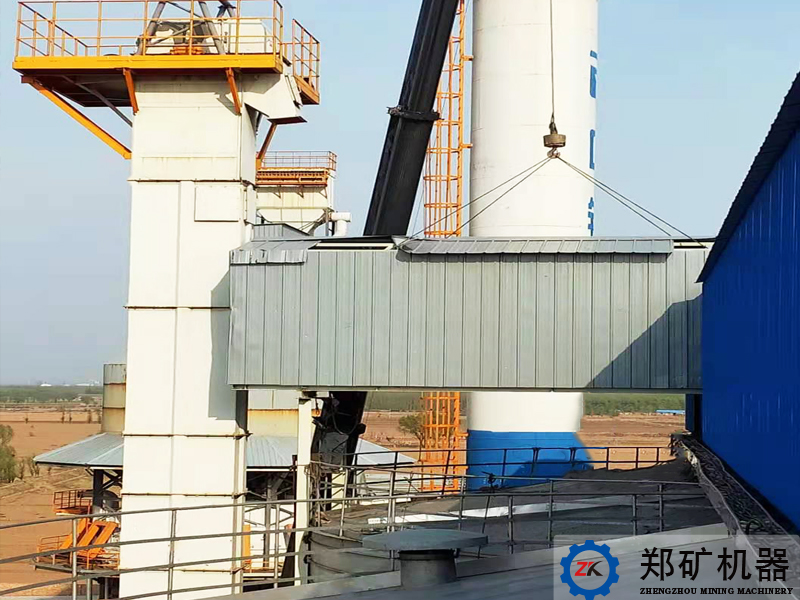

Project Introduction: This project is a production line project with annual output of 60,000 square expansion lightweight aggregate, and the elevator is mainly used to lift glass powder, ceramic powder, limestone powder, etc.

Equipment name: ne15×18m plate chain bucket elevator

Production capacity: 4~6 m³/h

Project Overview

Signing date: 2019.10

Product Name: ne15×18m plate chain bucket elevator

Processing Capacity: 4~6 m³/h

Equipment Configuration: NE15 × 18m plate chain bucket elevator

This project is a production line project of expanding lightweight aggregate with an annual output of 60,000 square meters. NE15 elevator is mainly used for lifting and transporting glass powder, ceramic powder and limestone powder, which has the characteristics of large conveying capacity, high lifting height, good overall stiffness of the chassis, tight sealing, etc.

This project is a production line project of expanding lightweight aggregate with an annual output of 60,000 square meters. NE15 elevator is mainly used for lifting and transporting glass powder, ceramic powder and limestone powder, which has the characteristics of large conveying capacity, high lifting height, good overall stiffness of the chassis, tight sealing, etc.

Working Principle

NE bucket elevator uses special lifting chain as traction component, Hopper is fixed on the lifting chain at a certain interval, and the lifting chain bypasses the chainwheel at the head and bottom of the elevator to form a closed ring system of rising loaded branch and falling unloaded branch. The driving device set on the head of the elevator passes the power to the lifting chain and Hopper through the head chainwheel; The material flows into the hopper from the feeding port at the bottom of the elevator, and the Hopper lifts the material to the unloading port of the head of the elevator along with the lifting chain. Under the dual action of centrifugal force and gravity, the material is unloaded from the unloading port.

Structural features

NE bucket elevator is mainly composed of upper device, lower device, transmission device, intermediate chassis, lifting chain, Hopper, maintenance platform, etc. Its main structural features are:

1. The lifting chain of the elevator is forged from low alloy steel, and after surface strengthening treatment, it has high tensile strength and good wear resistance to prevent the lifting chain from deviating;

2. The bottom is equipped with tensioning device, which can adjust the tightness degree of transmission chain by itself;

3. The Middle shell of the elevator is a steel plate bending welding structure, which has the characteristics of small weight, good rigidity and small welding deformation, significantly improving the overall performance of the equipment;

4. There are multiple inspection doors on the chassis, which can conveniently observe the operation status of lifting chain and Hopper, and also facilitate maintenance or replacement of Hopper and lifting chain;

5. Sealing devices are set between the shells and between the access door and the shells to realize clean and environmentally friendly production;

6. In order to prevent the tensioning sprocket from skew after being subjected to unbalanced tension, there is an automatic centering mechanism set at the lower sprocket device, which can adjust the centering and align itself according to the tension change;

7. The upper device of the elevator is equipped with a reliable reverse stopping mechanism, which can effectively prevent the traction parts and the loading hopper from retrograde;

8. According to the characteristics of the lifting materials, the feeding ports are divided into two types: high and low. Among them, the high position forms an angle of 60 ° with the horizontal plane, which is used to transport materials with poor scattering property such as humidity and powder; The low position forms an angle of 45 ° with the horizontal plane, which is used to transport materials with good drying and scattering property. The high position and low position of the feed inlet can avoid the congestion of the aggregate in the feed inlet, at the same time, reduce the running resistance of the elevator and increase the filling coefficient of the Hopper.

9. After years of manufacture, use and improvement, this series of plate chain bucket elevator has advanced and mature technology, which can reach a higher lifting height and a larger conveying capacity. It is easy to maintain and has strong operability in the process of use, and has been recognized by the vast number of users.